FAQs When Selecting the Right 3MTM Bonding Tapes for Your Product and Process

What materials are you bonding?

How will the assembly be used?

- Type of substrate or hard-to-bond materials

- Bonding dissimilar materials

- Configuration of your part (design/shape)

- Appearance and aesthetic considerations

- Need for disassembly for maintenance or service

How the product will be processed?

- Need high-speed bonding

- Need to be able to reposition

- Will be subjected to vibration

- Requires heat and/or pressure for bonding

- Desire to cut costs/increase production/simplify operation

How do you need the adhesive to perform?

- Match strength to stresses/combination of stresses: Tensile, Shear, Cleavage and Peel

- Flexibility

- Maintain surface integrity

- Permanent bond

- Resist heat and/or moisture

- Bond and seal

- Reduce risk of bimetallic corrosion and/or rust

Will the assembly be exposed to harsh environmental conditions?

- Very low or very high temperatures

- High humidity

- Chemicals

- Water

- Dirt/dust

Aesthetics and Surface Integrity

With uniform stress distribution of adhesives and tapes, lighter, thinner materials can be used without concerns about distortion, splitting, or crazing at the mechanically fastened site. Elimination of holes in metal also reduces the chances for rust and corrosion.

Bonds Subjected to Vibration

The viscoelasticity of many 3M adhesives and tapes improves resistance to vibration fatigue by imparting flexibility to a joint or bonded area.

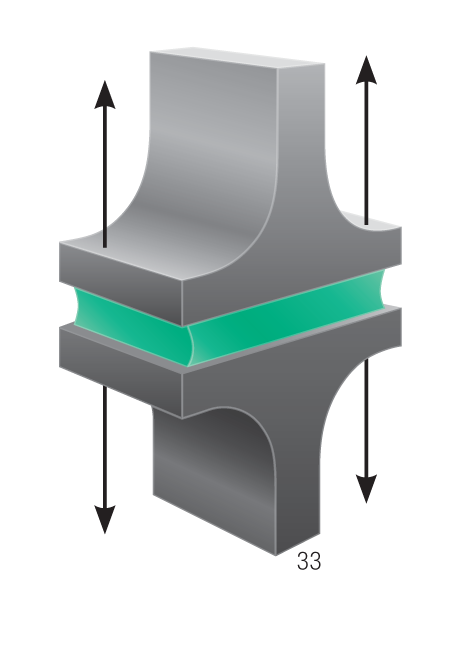

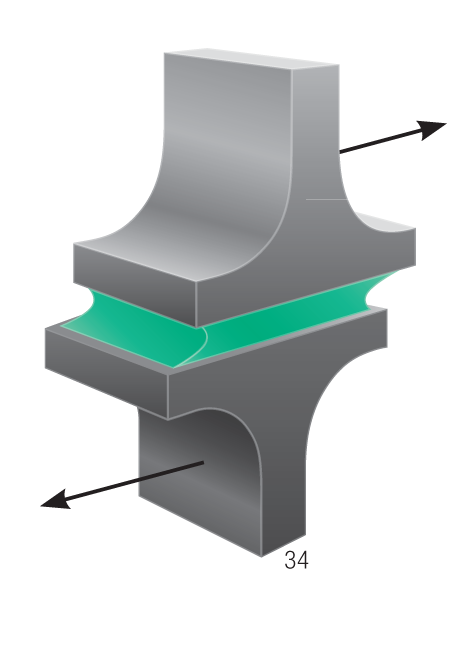

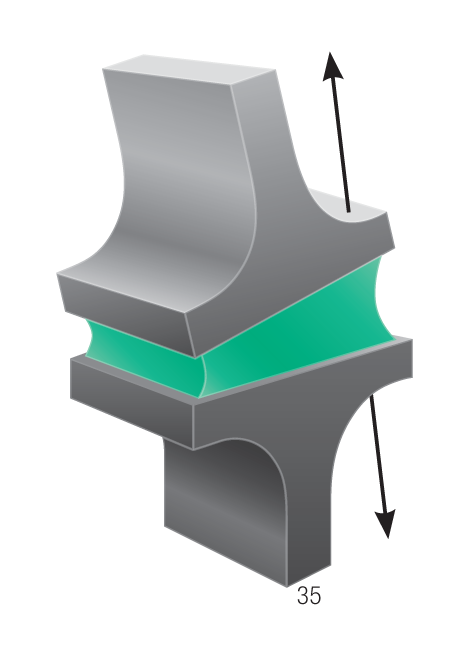

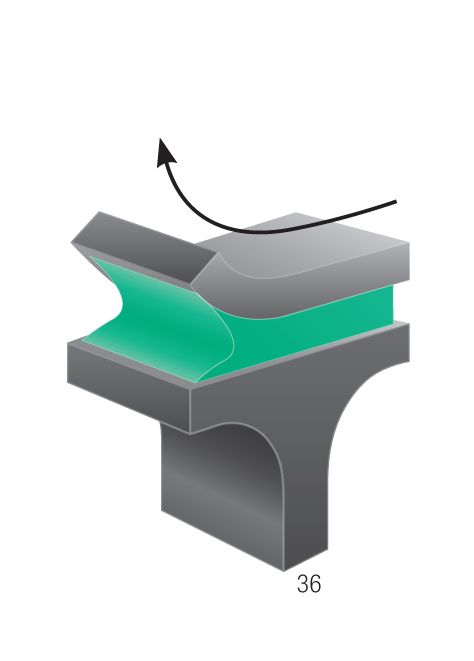

Different design challenges require different solutions. Illustration of potential stress on bonded joints.

Tensile is pull exerted equally over the entire joint. Pull direction is straight and away from the adhesive bond.

Shear is pull directed across the adhesive, forcing the substrates to slide over each other

Cleavage is pull concentrated at one edge of the joint, exerting a prying force on the bond. The other edge of the joint is theoretically under zero stress.

Peel is concentrated along a thin line at the edge of the bond where one substrate is flexible. The line is the exact point where an adhesive would separate if the flexible surface were peeled away from its mating surface. Once peeling has begun, the stress line stays out in front of the advancing bond separation.